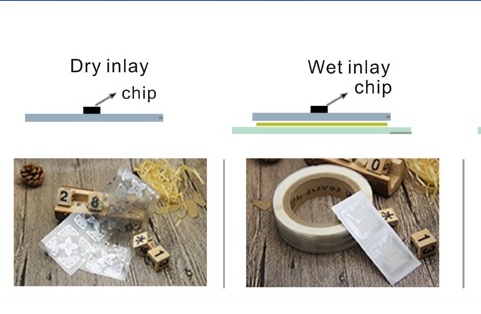

RFID wet inlays are passive RFID inlays with an adhesive backing that can be either applied to a product directly or converted into smart labels (integrated into a paper or plastic label). “Dry” inlay does not include the adhesive layer. Wet inlays are low cost solution to high volume tagging of products that do not require printed information on the tag.

As any passive tag, RFID wet inlay includes an integrated circuit (IC) or chip that stores and processes tag data and an antenna, which gathers power from the reader to power the tag and enable RFID communication. Passive RFID tags do not include a battery or a transmitter. For more information about passive RFID tags, please visit How to select a correct RFID tag – Active vs. Passive.

Our assortment of wet inlays constantly changes, so please check back often and let us know if you need help selecting or locating an inlay for a particular application!

What is RFID?

Radio-Frequency Identification (RFID) is the use of radio waves to read and capture information stored on a tag attached to an object. A tag can be read from up to several feet away and does not need to be within direct line-of-sight of the reader to be tracked.

How does a RFID system work?

A RFID system is made up of two parts: a tag or label and a reader. RFID tags or labels are embedded with a transmitter and a receiver. The RFID component on the tags have two parts: a microchip that stores and processes information, and an antenna to receive and transmit a signal. The tag contains the specific serial number for one specific object. To read the information encoded on a tag, a two-way radio transmitter-receiver called an interrogator or reader emits a signal to the tag using an antenna. The tag responds with the information written in its memory bank. The interrogator will then transmit the read results to an RFID computer program.

There are two types of RFID tags: passive and battery powered. A passive RFID tag will use the interrogator’s radio wave energy to relay its stored information back to the interrogator. A batter powered RFID tag is embedded with a small battery that powers the relay of information. In a retail setting, RFID tags may be attached to articles of clothing. When an inventory associate uses a handheld RFID reader to scan a shelf of jeans, the associate is able to differentiate between two pairs of identical jeans based upon the information stored on the RFID tag. Each pair will have its own serial number. With one pass of the handheld RFID reader, the associate can not only find a specific pair, but they can tell how many of each pair are on the shelf and which pairs need to be replenished. The associate can learn all of this information without having to scan each individual item.

RFID Tags

RFID Class-1 Generation-2 (“Gen-2”) tags are used for item level identification in retail environments. “Class-1” refers to the functionality of the tag while “Gen-2” refers to the physcial and logical standards of tag and the encompassing system. These standards are maintained by EPCglobal. “Gen-2” standards were adopted in December of 2004 and offer many advantages over “Gen-1” such as: – An interoperable, global standard – Faster and more flexible read speeds – Faster, more accurate performance through the use of advanced anticollision protocols – An easier way to deploy many readers at one time to end users – Enhanced sercuirty and privacy

RFID tags are classified as Class 0 through Class 5, depending on their functionality:

| Class 0 | UHFl read-only, preprogrammed passive tag |

| Class 1 | UHF or HF; write once, read many (WORM) |

| Class 2 | Passive read-write tags that can be written to at any point in the supply chain |

| Class 3 | Read-write with onboard sensors capable of recording parameters like temperature, pressure, and motion; can be semipassive or active |

| Class 4 | Read-write active tags with integrated transmitters; can communicate with other tags and readers |

| Class 5 | Similar to Class 4 tags but with additional functionality; can provide power to other tags and communicate with devices other than readers |

EPCglobal

EPCglobal® is a GS1 initative to innovate and develop industry-driven standards for the Electronic Product Code™ (EPC) to support the use of Radio Frequency Identification (RFID) and allow global visibility of items (EPCIS) in today’s fast-moving, information rich, trading networks. Standards have been developed in two areas:

The Electronic Product Code™ (EPC) is syntax for unique identifiers assigned to physical objects, unit loads, locations, or other identifiable entity playing a role in business operations.

EPCs have multiple representations, including binary forms suitable for use on Radio Frequency Identification (RFID) tags, and text forms suitable for data sharing among enterprise information systems.

GS1’s EPC Tag Data Standard (TDS) specifies the data format of the EPC, and provides encodings for numbering schemes — including the GS1 keys — within an EPC.

When unique EPCs are encoded onto individual RFID tags, radio waves can be used to capture the unique identifiers at extremely high rates and at distances well in excess of 10 metres, without line-of-sight contact. These characteristics of RFID can be leveraged to boost supply chain visibility and increase inventory accuracy.

EPCIS is a GS1 standard that enables trading partners to share information about the physical movement and status of products as they travel throughout the supply chain – from business to business and ultimately to consumers. It helps answer the “what, where, when and why” questions to meet consumer and regulatory demands for accurate and detailed product information.

The goal of EPCIS is to enable disparate applications to create and share visibility event data, both within and across enterprises. This sharing is aimed at enabling users to gain a shared view of physical or digital objects within a relevant business context.

EPCIS is intended to be used in conjunction with the GS1 Core Business Vocabulary (CBV) standard. The CBV provides definitions of data values that may be used to populate the data structures defined in the EPCIS standard. The use of the standardized vocabulary provided by the CBV standard is critical to interoperability and critical to provide for querying of data by reducing the variation in how different businesses express common intent.

Internet of Things (IoT)

What is IoT?

The Internet of Things (IoT) describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet. These devices range from ordinary household objects to sophisticated industrial tools. IoT is transformational to systems, devices, technologies and applications—across industry and around the world—driven by:

IoT has become one of the most important technologies of the 21st century. Now that we can connect everyday objects—kitchen appliances, cars, thermostats, baby monitors—to the internet via embedded devices, seamless communication is possible between people, processes, and things.

By means of low-cost computing, the cloud, big data, analytics, and mobile technologies, physical things can share and collect data with minimal human intervention. In this hyperconnected world, digital systems can record, monitor, and adjust each interaction between connected things. The physical world meets the digital world—and they cooperate.

- an expectation by businesses and consumers that all things will be “connected”

- increasing capabilities and lower cost of microcontroller and communications technologies

- the explosion of cloud-based data gathering, processing and sharing platforms

GS1’s “Global Language of Business” connects the physical and digital worlds. Identification of objects, assets, locations, etc. and automatic data capture are powered by GS1 barcodes and EPC/RFID. GS1 standards for data sharing enable interoperable, trusted and transparent data which are foundational to unleashing IoT capabilities.

GS1 also provides a trusted foundation for the responsible use of the technologies behind its standards—paving the way for the future of IoT by providing best practices for risk assessment and data protection.

What Is Industrial IoT?

Industrial IoT (IIoT) refers to the application of IoT technology in industrial settings, especially with respect to instrumentation and control of sensors and devices that engage cloud technologies. Recently, industries have used machine-to-machine communication (M2M) to achieve wireless automation and control. But with the emergence of cloud and allied technologies (such as analytics and machine learning), industries can achieve a new automation layer and with it create new revenue and business models. IIoT is sometimes called the fourth wave of the industrial revolution, or Industry 4.0. The following are some common uses for IIoT:

- Smart manufacturing

- Preventive and predictive maintenance

- Smart power grids

- Smart cities

- Connected and smart logistics

- Smart digital supply chains